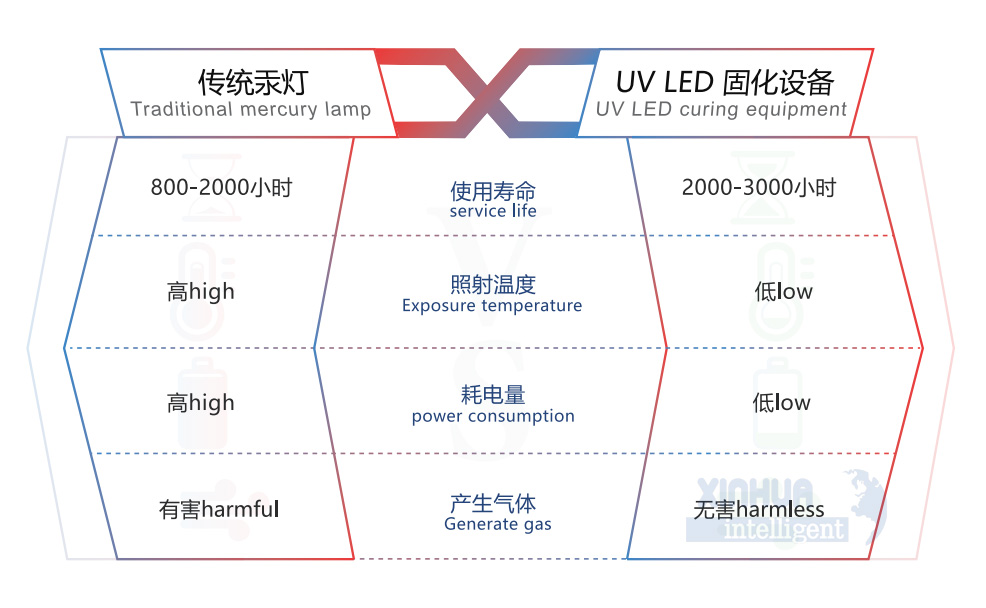

| Traditional mercury lamp | Vs | UV LED curing equipment |

|---|---|---|

| 800~2000 hours | service life | 2000~3000 hours |

| high | Exposure temperature | low |

| high | power consumption | low |

| harmful | Generate gas | harmless |

UV Energy: The energy can be adjusted by adjusting the power and exposure time. If the energy is insufficient, the exposure time can be increased.

Safety Protection: The UV LED will automatically alarm if the temperature is too high, and it has open-circuit protection, short-circuit protection, shading treatment, and exhaust gas emission functions.

Monitoring Functions: It can realize the monitoring of exposure time, real-time detection of energy/temperature, alarm record function, energy upper and lower limit warning function, and furnace temperature monitoring function.

Individual LED Monitoring: It can monitor the damage and energy abnormality of individual LEDs in real time to avoid the situation where the glue layer fails.

| Models | XY-UV1600F-S LED |

|---|---|

| Track travel | 450mm(Customizable) |

| Track length | 1600mm(Customizable) |

| Irradiation area | 530*200MM/530*100MM(Customizable) |

| Recommended exposure distance | 10~50MM |

| Maximum load | 5kg |

| Number of tracks | Monorail/double rail/triple rail |

| Transfer operation mode | Flow operation |

| Control system | PLC control |

| Operation mode | Interface |

| Single lamp bead damage alarm | Optional |

| Energy real-time detection | Optional |

| Conveyor material | sheet metal |

| Heat dissipation mode | Water cooling/air cooling |

| Exhaust mode | The exhaust pipe is connected to the workshop blower interface |

| Device power consumption | 8KW |

| Input power | AC220V 50/60HZ |

| Overall dimension | L1600*W750*H1750mm(The actual product shall prevail) |

| Weight | around 500kg |

XY-UV2000 LED Curing Lift UV Oven

The lifting structure breaks the efficiency bottleneck and reduces the footprint.UV LED curing real-time monitoring of individual LED damage and energy anomalies, glue stratification, failure and other situations.

| Model | XY-UV2000 |

|---|---|

| Track travel | 450mm |

| Track length | 2200mm*500mm |

| Irradiation area | 500*200MM*2/500*100mm*2 (customizable) |

| Recommended exposure | 40-70MM |

| Maximum load | 5kg |

| Number of tracks | double rail |

| Transfer operation mode | Flow operation |

| Control system | PLC control |

| Operation mode | interface |

| Single lamp bead | Optional |

| Energy-real-time detection | Optional |

| Conveyor material | sheet metal |

| Heat dissipation mode | Water cooling / air cooling |

| Exhaust mode | The exhaust pipe is connected to the workshop blower interface. |

| Device power consumption | 12KW |

| Input power | AC380V 50/60HZ |

| Overall dimension | W2300*L1500*H2340mm (standard) |

| Weight | around 1300kg |

UV LED Surface Light Source Curing Equipment

The newly developed UV LED surface light source curing equipment with light intensity of 900MW / cm² and luminous area of 200 * 50 nm. It has the characteristics of high ultraviolet radiation intensity and good spot uniformity. The simple and intelligent control system and high-power LED chip module provide guarantee for the high efficiency and quality stability of curing, and can meet the perfect use of customers in many fields. Reliable, stable and shorter curing time are very important indicators.

- The LED beads are imported UV LED beads with slow attenuation and long service life.

- LED lamp beads are equipped with protection functions such as short circuit, overcurrent and overtemperature.

- The light source power can be set independently and displayed as a percentage, and the power adjustment accuracy can reach 1% (Curing equipment starting power (8-10%)).

- It has automatic, manual, step, pulse and other irradiation modes.

- Equipped with perfect external I/O control interface to realize perfect connection with automation equipment.

- Touch operation panel, simple and intuitive operation.

- Scientific heat dissipation structure design to ensure that the operating temperature of the equipment is within the normal range and the constant output of optical power.

| Number | Project | Specification |

| 3.1 | LED type | ultraviolet LED |

| 3.2 | LED wavelength | 365/395/405nm |

| 3.3 | LED life | 20000 hours |

| 3.4 | Optical power | 900mw/cm² |

| 3.5 | Irradiation area | 200×50nm |

| 3.6 | Irradiation distance | 30mm~50mm |

| 3.7 | Power waste | 300W |

| 3.8 | Cooling | strong wind mode |

| 3.9 | Dimension | controller:300mm(L)*4205mm(W)*138mm(H) lighting head:252mm(L)*75mm(W)*73mm(H) |

| 3.10 | Power supply specification | 1.220VAC/50HZ/250W 2.the machine with 2 meters long wire |

FAQs

What is the minimum order quantity (MOQ) for your products?

Can I customize the products according to my specific requirements?

What payment methods do you accept for orders?

We accept a variety of payment methods including bank transfer, PayPal, and letter of credit (L/C). Payment details will be confirmed during the order process.