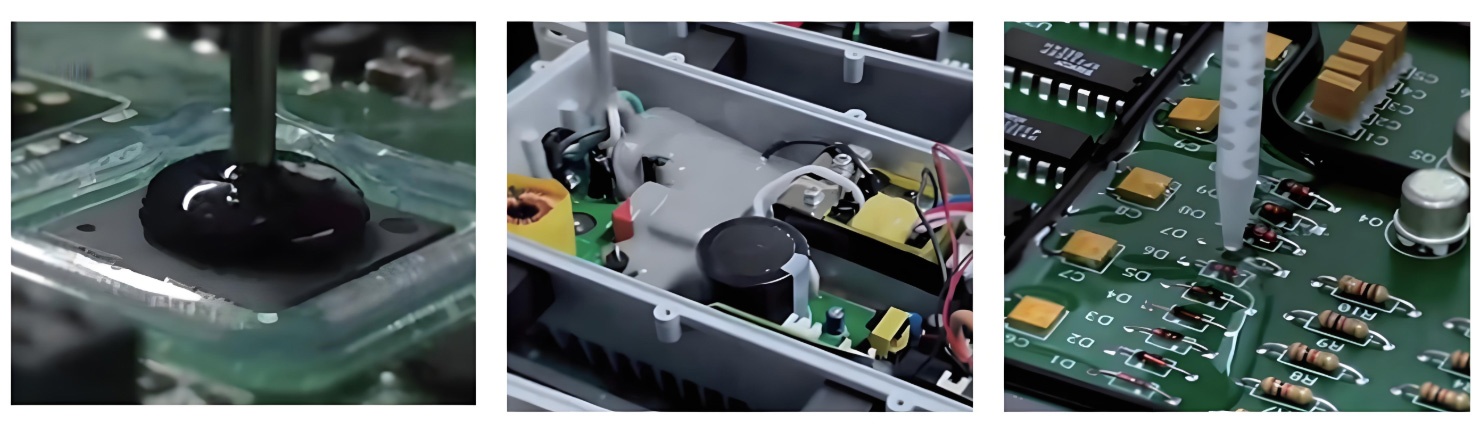

Our glue potting machine Series delivers exceptional performance through versatile operation modes including single action, linkage, and fully automatic functions. Engineered for precision manufacturing, these systems maintain superior proportioning accuracy at ≤±3% and ejection accuracy at ≤±3%, ensuring consistent results for your most demanding applications. The highly adaptable mixing ratio ranging from 1:1 to 20:1 is fully customizable to meet your specific material requirements, while the adjustable glue dispensing speed of 0.1~50g/s can be precisely calibrated according to your product conditions. Featuring both dynamic and static mixing options, our machines accommodate various viscosity materials and production needs. For extended production runs, the optional anti-curing function prevents material hardening in the system, minimizing downtime and maximizing productivity. Experience the perfect balance of precision, flexibility, and reliability with our glue potting machine series – designed to elevate your manufacturing process.

- High Precision Filling - Ensures accurate and consistent glue application.

- Customizable Settings - Adjustable parameters to meet various production needs.

- User-Friendly Operation - Intuitive controls for easy setup and maintenance.

AB automatic glue potting machine is mainly used for double liquid AB glue. Its main function is to mix the two kinds of AB glue well, mix them evenly, squeeze them out and automatically fill them into each product. In short, it is composed of material barrel, metering pump, metering motor, conveying pipe, double liquid glue valve, dynamic mixing motor, mixing pipe and three-axis manipulator platform. The glue A and B are completely separated in the whole process from the glue entering the material barrel, metering pump, material conveying pipe and double liquid glue valve, so the glue will not solidify in the equipment. Adjust the proportion of glue by adjusting the speed of the motor and measuring the weight of AB glue respectively. The glue is quantitatively output to the double liquid glue valve. Through the dynamic mixing pipe, the high-speed motor drives the mixing core to rotate, so that the glue can be fully and evenly mixed and quantitatively extruded into the product. Double liquid glue moistening has the function of sucking back and preventing leakage. When the glue potting operation of a single product is completed, it can quickly break the glue without wire drawing and dripping. For different glues and different product requirements, the material bucket mixing function is configured, so that the glue will not precipitate and layer when stored in the material bucket. The material barrel has the function of defoaming to remove the bubbles contained in the glue in the barrel. Heating constant temperature function, barrel heating, metering pump heating and conveying pipe heating to ensure consistent fluidity of glue and avoid changing the density of glue due to viscosity change of glue.

The glue potting system cooperates with the three-axis manipulator to complete the automatic glue potting operation of the product. The manual only needs to arrange the products to the equipment glue potting platform in turn, set the glue potting position and quantity, and press start. The glue potting program can store 1000 groups, which can fully meet the glue potting of different kinds of products. The touch screen man-machine interface and handheld programmer are used to set the glue potting program. The operation is simple and convenient, easy to learn and understand. It does not need to be equipped with professional operators, which is more worry-saving and labor-saving. There is no need to worry about the problem that the machine is not taken over due to the resignation of personnel.

The circulation system of the glue potting machine mainly includes a metering pump, a conveying pipeline, a circulation pipeline, valves, and a storage tank The outlet of the circulation pipeline is connected to the inlet of the storage tank, and the outlet of the storage tank is connected to the metering pump through the conveying pipeline. The inlet of the circulation pipeline is connected below the conveying pipeline By increasing the design of the circulation pipeline, the potting material that settles in the pipeline can be refluxed to the storage tank, which not only saves material costs but also effectively prevents the potting material from depositing and blocking the pipeline in the sealed pipeline, eliminating the process of dismantling and cleaning the pipeline.

FAQs

What is the minimum order quantity (MOQ) for your products?

Can I customize the products according to my specific requirements?

What payment methods do you accept for orders?

We accept a variety of payment methods including bank transfer, PayPal, and letter of credit (L/C). Payment details will be confirmed during the order process.